Next-Gen Aircraft Specs: Achieving Tight Tolerances on Aerospace Parts and Keeping Pace with the Industry

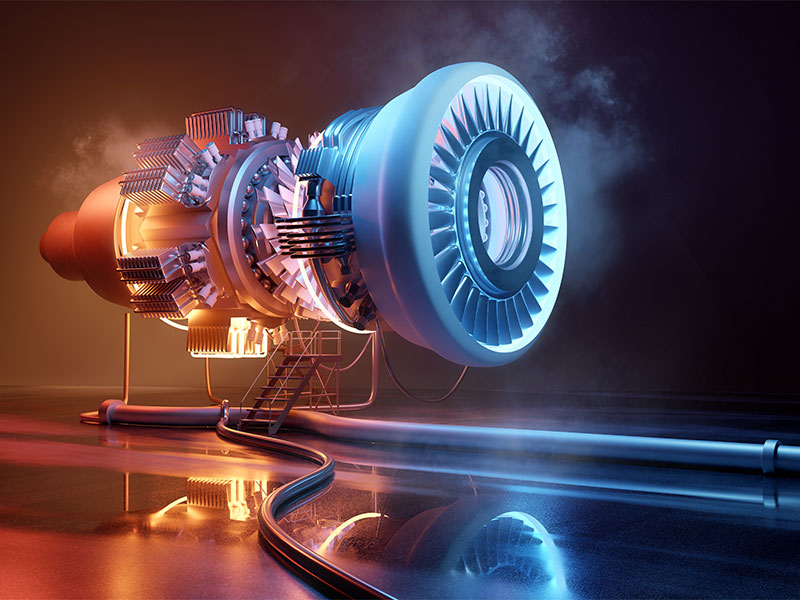

Modern industries need modern solutions. The Aerospace industry is an excellent example of that. This market has been changing, growing, and innovating so quickly that keeping up with the market and the stringent tolerance and quality standards at the same time can be difficult. We would know–manufacturing aerospace parts is one of our specialties here at A&G Machine. As an AS9100 and Boeing certified manufacturer, we’re familiar with the stringent requirements of the modern-day aerospace industry, and we have the knowledge and the equipment to achieve micro-tolerances and surface finishes crucial for our partners.

Advanced Five-Axis CNC Machining

Achieving extremely tight tolerances is difficult but necessary in aerospace manufacturing to prevent premature wear and operating failures. Plus, the smaller and more intricate the part, the more difficult it is to machine. At A&G, we specialize in 5-Axis CNC machining, one of the most versatile and efficient CNC technologies available. Not only can we achieve extremely tight tolerances, we can also keep up with the fast-paced needs of the industry.

Our machines can create aerospace parts with less need for downtime between different operations or re-orientation of the workpiece, and they also achieve much more complex shapes thanks to the tooling being able to work on the part from multiple angles. Combine that with A&G’s high-speed machining capabilities and the various automated CMMs integrated throughout our facility, and we’re able to deliver high quality, innovative solutions quickly and efficiently for our customers.

Maintaining Precision for Parts Large and Small

Modern manufacturing isn’t just about advanced technology–it’s also about packing more functionality into a single part, which means creating more complex and larger components to avoid potential issues that arise with assemblies of multiple simple and smaller components. A&G supports our aerospace manufacturing partners through large-scale machining of complex aerospace parts.

For instance, we’ve created fuselage frames, wing spars and ribs, and other larger components, many of which have similar complexity and tolerance requirements as smaller parts. And we have high-speed gantries and machining equipment to achieve all of this on time so that our customers can maintain their competitive edge in this fast-paced industry. Combined with automated metrology and inspection, A&G maintains strict quality and precision on these larger components and assemblies.

Looking for an expert in aerospace parts manufacturing?

A&G Machine, Inc. has been a trusted partner for some of the world’s top aircraft manufacturers for years, supplying them with precision machined aerospace parts and quality service that offers a modern solution to today’s fast-paced markets. Head over to our website to check out our capabilities for yourself and partner with a manufacturer that you can trust.